1、Photovoltaic industry

Application background:

In order to implement the goal of photovoltaic power generation on the grid at the end of the 13th Five-Year Plan, and realize the requirement of "photovoltaic power generation and grid sales price by 2020" put forward in the National Energy Development Strategic Action Plan. Along with the continuous improvement of solar cell efficiency and the sharp decrease of component cost, together with the scale effect of the rapid increase of installed photovoltaic power plants during the 12th Five-Year Plan period and the gradual improvement of the photovoltaic power industry chain, not only the price of photovoltaic modules has dropped, but also the price of inverters has dropped sharply. Therefore, in recent years, the unit kilowatt investment of photovoltaic power plants in China is also declining. 。 In view of the fact that the cost of battery components has decreased by nearly 10 times between 2007 and 2014 in China, the cost of photovoltaic power generation is expected to be equal to that of thermal power generation in 2020, so the potential of photovoltaic power generation is huge.

The main component of solar cell module used in photovoltaic power generation is silicon wafer. At present, the production and processing of silicon wafer can not be separated from diamond wire cutting with high carbon steel microwire as core material. Therefore, the application of high carbon steel microwire will continue to increase in the photovoltaic industry in the next decade.

Application background:

Magnetic materials are widely used in electroacoustics, telecommunications, watt-hour meters, motors, memory elements, microwave elements, tapes for recording language, music, image information, magnetic storage devices for computers, passenger vouchers and magnetic cards for fare settlement, etc. In terms of material and structure, it can be divided into "metal and alloy magnetic materials" and "ferrite magnetic materials". Ferrite magnetic materials can also be divided into polycrystalline and single crystal structure materials. From the application function, it can be divided into soft magnetic materials, permanent magnetic materials, magnetic recording - moment magnetic materials, spin magnetic materials and so on. The metal will produce huge eddy current effect at high frequency and microwave frequency, which will make the metal magnetic material unusable, and the resistivity of ferrite is very high, which will effectively overcome this problem and be widely used. Morphologically, it can be divided into powder material, liquid material, bulk material, film material, etc.

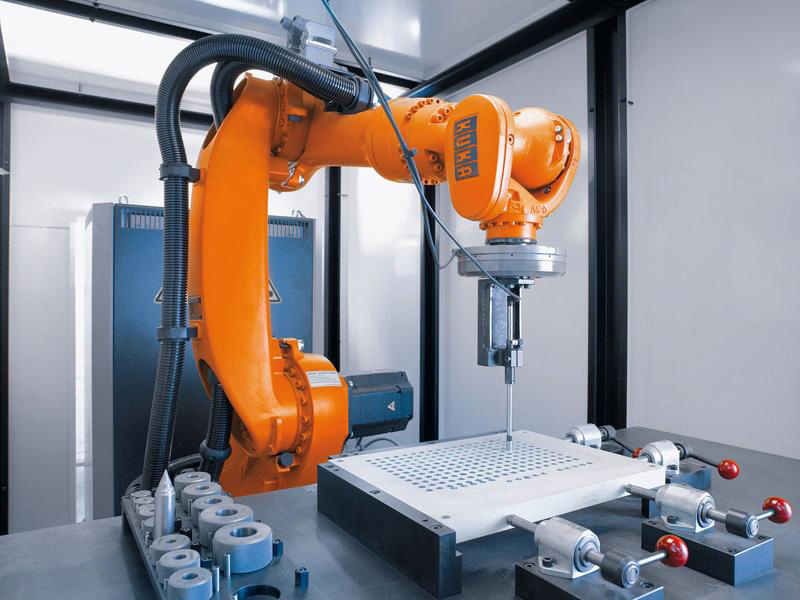

In such a wide range of applications, the demand for magnetic materials has increased dramatically, such as new energy vehicles and high-speed railways, metro, "industrial 2025" automation industrial manufacturing needs to use a large number of permanent magnet motors, which have the advantages of light weight, energy saving and so on. In addition, the technology of multi-wire cutting has completely replaced the technology of internal circular slicing, which has brought about great changes in the processing of magnetic materials.

3、Sapphire and SemiconductorApplication background:1、Sapphire Cutting Demand Rises;

Nowadays, the demand of LED replacing incandescent lamp, fluorescent lamp and intelligent terminal window is increasing rapidly, which leads to the rapid growth of sapphire substrate material demand in LED industry and the wide application of optical sapphire materials in consumer electronics industry.

2、Semiconductor demand is also increasing rapidly: smart terminals, smart homes, smart cars, smart robots, virtual reality and so on are on the eve of the outbreak, as well as new formats such as 5G, the Internet of Things, artificial intelligence, block chains and so on, all of which form a huge demand for semiconductor components such as chips and crystal oscillators.

Address:Building H, Suzhou Intelligent

Address:Building H, Suzhou Intelligent Tel:400 900 7270

Tel:400 900 7270

Fax:0512-67509525

Fax:0512-67509525

E-Mail:sales@apintec.com

E-Mail:sales@apintec.com