| target | Importance | Test frequency |

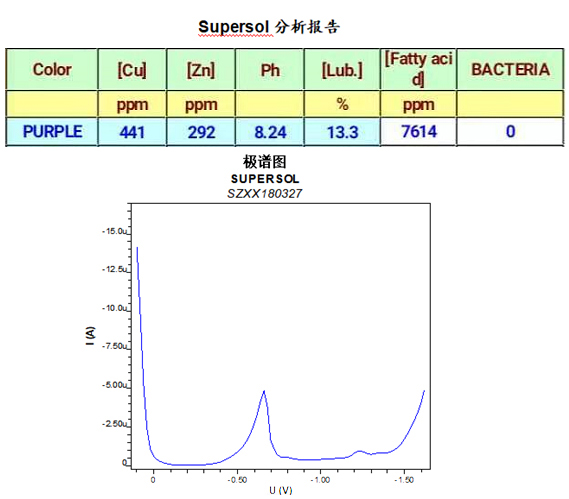

| PH value | Keeping the PH value stable in the production process is beneficial to maintaining the chemical balance of lubricants. | everyday |

| potency | In order to maintain excellent lubrication performance, the bath concentration must be stable. Too much or too little will cause adverse consequences. | everyday |

| temperature | Bath life will be reduced if the temperature is higher than 50 C. Bacteria will multiply if the temperature is too low. | everyday |

| Cu、Zn concentration | Metal ions are necessary in lubrication, but too high a content can be harmful. | weekly |

| Fatty acid content | Fatty acid is an important additive to maintain lubrication performance. Maintaining a certain content of fatty acid can produce good lubrication effect. | weekly |

| Bacteria | Bacteria can consume fatty acids, and excessive bacteria can lead to deterioration of lubricant performance. | weekly |

| Polarography | Investigation of the overall aging degree of lubricants | weekly |

Address:Building H, Suzhou Intelligent

Address:Building H, Suzhou Intelligent Tel:400 900 7270

Tel:400 900 7270

Fax:0512-67509525

Fax:0512-67509525

E-Mail:sales@apintec.com

E-Mail:sales@apintec.com